Notable Project Achievements

We work with companies of all sizes, including several of the Fortune 50 as well as many mid- and small-cap companies. Our projects include questions of strategy, tactics and operations. Regardless of the size or scope of the question, Caplan has an established record of delivering significant cost avoidance, productivity improvements and other savings.

Established vendor capability and a sourcing master plan

Our client asked us to evaluate a new contract manufacturer in South Africa. We audited the plant’s existing infrastructure and operations, identified current and future bottlenecks and presented a capacity glidepath outlining the scope required to place additional volume with the supplier as our client’s business expanded in the local market.

5-year Site Master Plan to support doubling the site’s volume

Following the rapid growth of a core brand in the region, this plant had reached its maximum capacity and category management had appropriated more than $200 million to expand its operations. Our study resulted in a 5-year growth plan that identified the PP&E, logistics, and staffing requirements necessary to support the expanding business.

10-year Site Master Plan

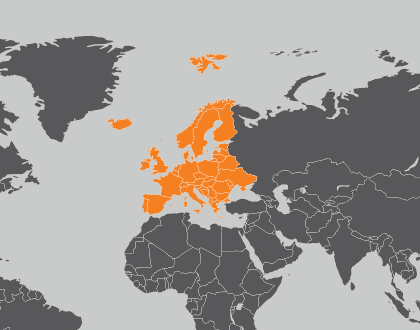

This $75+ million project included the strategic planning for a single-category new site in Poland. Caplan’s involvement included project team facilitation, candidate property analysis, site selection, facilities planning and logistics support.

$3 million in annual going cost savings

Caplan was hired by this consumer products company to evaluate the operating strategy of its second-largest plant and distribution center. Following an in-depth Site Assessment, Caplan developed and implemented a new economic production model (S&OP) and an inventory replenishment model at the combined site. After 9 months, the site reported a 25% increase in productivity and a 50% decrease in finished product storage levels (a $3 million+ annual going-cost reduction).

5-year Master Plan to support increasing site volume

This plant’s site was fully developed and management had allocated more than $20 million to optimize and/or re-organize current operations to increase throughput. Our study resulted in a 5-year plan that identified PP&E, logistics, staffing, phasing and capital requirements necessary to support the growing business.